- The SCADA Modbus OPC Server (Telemetry / OPC DA) is OPC Certified! OPC Certification is the process of ensuring that applications meet the standards specified by the OPC Foundation. OPC Certification requires extensive testing to ensure true interoperability. OPC Certification means multi-vendor system interoperability is guaranteed.

- Search for existing questions or post your own. Ask users like you who have solved similar challenges to help.

- Using award-winning technology, Intellution provides an industry-standard software platform that collects, distributes, controls and visually presents information from the plant floor throughout the enterprise, supplying customers with scalable solutions that deliver increased productivity and return on investment.

- Desktop based scada software Development, desktop based scada software Development in india, customized scada applications,plc and customized scada applications, SCADA Software Development mumbai,plc and intellution scada solutions, scada solutions for industrial applications mumbai, SCADA Support Application Development mumbai, Device Interface SCADA Applications, device interface customized.

- At GE, we use our own HMI/SCADA software. We demand the highest reliability, including during version upgrades, and we test continuously. Unlike some other HMI/SCADA software, iFIX is not Java based.

- Upgrade your HMI/SCADA software to give you access to valuable real-time operational intelligence. Add a data historian to view key performance metrics and complete a more complex analysis of your operations. Take the first step in transforming data in to actionable information.

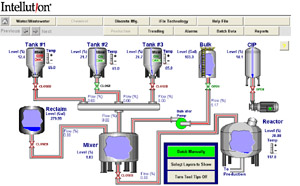

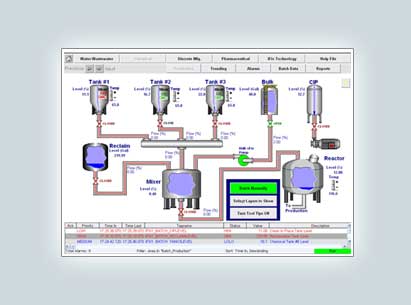

Refer to the alarm common message format configuration menu accessed through the Intellution SCADA/View node software package. Figure 1: Intellution Alarm Message Format Configuration Menu. Using Figure 1 as an example, the starting string position is 68 and the data string length is 13.

In its time, Intellution’s FIX32 was a powerful automation solution that took full advantage of Windows 95 and Windows NT’s powerful capabilities.

At the time, FIX32 had more 32-bit installations than all other automation software vendors combined. But that time has passed and HMI/SCADA solutions have come a long way since then.

In its current iteration, iFIX 6.0, offers support for the latest software standards, a robust SCADA engine, rich set of connectivity options, open architecture and highly scalable and distributed networking model.

iFIX is a superior proven real-time information management and SCADA solution, which is open, flexible and scalable.

The product is constantly evolving. A recently developed iPad app, coupled with iFIX Webspace©, is allowing operators to easily and quickly harness the power of iFIX or CIMPLICITY on the iPad with minimal engineering effort.

Unfortunately, there are a many misconceptions surrounding the upgrade from FIX32 to iFIX. Horror stories of complicated installations abound. Fears of a complete systems re-architecture keep companies from moving forward.

The good news is, if properly pulled off, the move from FIX32 to iFIX can be relatively painless.

The purpose of this document is to dispel some of the myths around moving from FIX32 to iFIX so you can harness the power of this solution and move forward.

Best Scada Software

Misconception 1: I don’t need to do an upgrade – we have been running our plant without it for years.

If it isn’t broke, don’t FIX it, right? Wrong.

Trust us — your it department wants you to keep up with the latest Microsoft technology. iFIX delivers support for all the latest Microsoft operating systems including Windows 7!

There are many things that are enabled by moving to the new platforms such as easy to maintain historical data, centralized maintenance of configuration and pictures, thin clients, mobility (ipads), and web based clients.

Misconception 2: My current strategy — HMI With FIX32 — is adequate.

There are significant advantages in moving to iFIX.

There were over 300 “voice of the customer” recommendations incorporated into just the first version of iFIX. Since then it has undergone many majors releases all the way to version 5.8 and soon 6.0.

Here’s a few improvements to iFIX over the years:

- Increased reliability

- Improved trending

- The iFIX workspace

- Advanced failover capabilities

- VisiconX interfacing to relational data

- A vast IO driver library

- A VBA based script environment

- Integrated Windows security

Misconception 3 – An upgrade from FIX32 to iFIX will take too long to implement.

Simply not true.

As with any project, it depends on proper planning and a sound road map for attack. Our 20 years of experience with these kinds of projects tell us that having someone on the team that has been there and done doesn’t hurt either.

The biggest reason we have seen upgrades projects take a long time is the normal project problem of “scope creep.”

Fact: Most items that are done in an upgrade project that push the deadline back further and further are really new pieces of scope.

Misconception 4 – An upgrade is too risky to implement and hard to get started.

There are plenty of experts to help you in this and guide your journey. For example, we have over 15 experts just in our company who can do this task completely or be available as a project team member or coach.

As one of the leading products in the marketplace, there is an entire ecosystem around the world to support iFIX. With the modern environment that is extensible, it is easy for an automated tool to be used to aid the upgrade process as well.

Misconception 5: It will be too expensive and it’s like starting over. Should I just switch out to another brand of HMI?

GE has spent millions of dollars on upward compatibility so that you don’t have to.

The concept of the FIX desktop can even re-use all of your FIX32 graphics complete with script files if you wish. Or the conversion utility can help you migrate the old pictures completely to the native iFIX format.

There are also many wizards and productivity tools that we

can show you to help work within the new environment. Even

though you have driven your old ride for a lot of miles there is an attractive trade in policy that we can walk you through that is commercially viable. Your investment is protected today and tomorrow – 350,000 installations worldwide can attest to that.

Misconception 6: You will need a ton of training and the iFIX system is hard to learn and come up to speed on.

In our experience, if you understand how the FIX32 system works, you will be able to navigate your way around the iFIX with limited trouble.

The database builder concept is fairly similar and is still the backbone of the system. A concept of the “workspace” development and runtime replaces View and Draw.

We find that most engineers that maintained a FIX32 system can maintain an iFIX system. Instead of training, sometimes some assistance in doing the upgrade is prudent since it may be a one-time occurrence for your plant or facility.

However, if you still want to go the training route, we can certainly suggest a place to find the best classes available.

Still not convinced? Consider this: With iFIX 5.5, there is no need to manage multiple drivers in SCU anymore. Instead, you can use one IGS driver – a single interface, communicate with multiple vendor’s controllers (the IGS driver offers more than 100 protocols).

Misconception 7: Doesn’t GE own iFIX now and don’t they also own CIMPLICITY? My competitor sales person told me that GE was getting rid of one or both of them.

There are significant customer bases in both products.

There is also shared technology in IO drivers, encryption, historical archiving, web, advanced analytics, MES and mobility solutions. There is a robust product team, support team, and product roadmap for both iFIX and CIMPLICITY.

Intellution Scada Software Free

Misconception 8: The decisions I need to make about my systems are hard and complicated.

We are not going to sugar coat the situation, there are some good engineering trade offs to think about since there is so many more options with the new computing power and new software power. Here’s a question we get all the time:

“Should I replace my distributed architecture SCADA (which was more common earlier) and go with a redundant pair after the upgrade?”

In this case there are issues like duplicate tag names, picture directory locations, thin clients and the proper failover technique to choose. But this is all good news!

These are things that weren’t even possible when you installed the last system. You can stick with the current architecture and make no changes — no problem. But here’s the upside: the options for improvement are great as well.

Misconception 9: All HMI systems are about the same.

Not true. Some HMI systems deliver unique capability and iFIX does for sure. For example:

- Mobility (iPad) support

- True failover for redundancy systems and high uptime

- Intelligent alarming

- The ability to integrate workflow and electronic standard operating procedures.

- In addition the unmatched ecosystem, the investment, and support power of GE make a commitment to iFIX a smart choice.

| Private (subsidiary of General Electric) | |

| Industry | Industrial Internet technology |

|---|---|

| Founded | Charlottesville, Virginia (1987) |

| Headquarters | Charlottesville, Virginia , |

Area served | Worldwide |

| Rob McKeel, General Manager | |

| Products | Industrial software and embedded computing platforms |

| Parent | General Electric |

| Website | www.geautomation.com |

General Electric Automation and Controls division combines what was formerly known as GE Intelligent Platforms and Alstom's Power Automation and Controls.

GE Automation and Controls produce power and cooling products, distributed control systems, remote monitoring and diagnostics, and support services including the design and commissioning of pre-engineered systems. Industries served include OEMs, power, oil and gas, manufacturing, military and aerospace, mining and metals, telecommunications, and water and wastewater industries.[1]

- 1History

History[edit]

In 1986, GE Fanuc Automation Corporation was jointly established in the US by FANUC and General Electric (GE). Under the joint venture company, three operating companies, GE Fanuc Automation North America, Inc., in the U.S., GE Fanuc Automation Europe S.A. in Luxembourg, and Fanuc GE Automation Asia Ltd. in Japan were established (the Asian company was established in 1987).

In 2007, the company was renamed to GE Fanuc Intelligent Platforms (and GE Fanuc Automation Solutions Europe SA became GE Fanuc Intelligent Platforms Europe SA). GE Fanuc Automation CNC Europe changed its name to Fanuc GE CNC Europe.

In 2009, GE and Fanuc agreed to dissolve joint venture and the software, controls and embedded business became part of GE, under the new name GE Intelligent Platforms.

In 2015, GE Intelligent Platforms, Inc. changed its name to Automation & Controls upon acquisition of Alstom's Power Automation & Controls business.

In 2018, amidst ambitious restructuration plans for the whole General Electric group, it was announced that Emerson Electric was to acquire Intelligent Platforms[2], and the deal was completed on February 1st, 2019[3].

Acquisitions[edit]

- 1998: completed acquisition of AFE Technologies (first purchased 70% in late 1996)

- 1998: acquired Total Control Products

- 2000: acquired DataViews Corp

- 2001: acquired VMIC

- 2002: acquired Intellution, Inc.

- 2003: acquired RAMiX

- 2003: acquired Mountain Systems, Inc.

- 2006: acquired (technology assets of) Condor Engineering

- 2006: acquired SBS Technologies

- 2006: acquired Radstone Technology PLC

- 2008: acquired process technology assets from MTL Instruments Group

- 2011: acquired SmartSignal, Inc

- 2011: acquired technology assets of CSense Systems (Pty) Ltd.

- 2015: acquired Alstom Power Automation & Controls

- 2015: sold its embedded systems division to Veritas Capital, now known as Abaco Systems[4]

References[edit]

- ^'GE Automation & Controls | Automation World'. www.automationworld.com. Retrieved 2016-01-05.

- ^https://www.nasdaq.com/article/emerson-to-acquire-intelligent-platforms-general-electric-unit--quick-facts-20181002-00305

- ^Acquisition grows Emerson’s presence as complete automation solutions provider for process, hybrid and discrete end markets

- ^'Abaco Systems, Former GE Embedded Technology and Systems Business Launches, Prioritizes Innovation and Customer Service'. Business Wire. Berkshire Hathaway. Retrieved 29 January 2016.